Overview of the 7th Edition of “Fundamentals of Modern Manufacturing”

The 7th edition of Fundamentals of Modern Manufacturing provides a comprehensive update on materials, processes, and systems, offering insights into modern manufacturing practices and technologies. It incorporates recent advancements in automation, quality management, and production control, making it a valuable resource for both students and professionals in the field. The textbook is available in various formats, including PDF and eBook, ensuring accessibility for diverse learning preferences.

1.1 Key Features of the 7th Edition

The 7th edition of Fundamentals of Modern Manufacturing offers a comprehensive upgrade with enhanced coverage of materials, processes, and systems. It introduces updated chapters on automation, quality management, and production control, reflecting current industry trends. The textbook includes expanded sections on advanced manufacturing technologies and sustainable practices, providing students with practical insights. New case studies and real-world examples have been added to improve understanding. The 7th edition also features revised illustrations and diagrams for clearer explanations. Additionally, it incorporates digital learning tools, such as online resources and interactive simulations, to support modern educational needs. The book remains a cornerstone for engineering students and professionals seeking to stay updated on modern manufacturing techniques and methodologies.

1.2 Relevance of the 7th Edition in Modern Manufacturing Education

The 7th edition of Fundamentals of Modern Manufacturing is a pivotal resource in contemporary manufacturing education, bridging theory and practice. Its updated content aligns with current curricula, addressing automation, sustainability, and advanced technologies. The textbook’s structured approach makes it ideal for both undergraduate and graduate courses, providing foundational knowledge and fostering critical thinking. Its integration of real-world case studies and practical examples prepares students for industry challenges. The inclusion of digital tools enhances learning, catering to modern pedagogical methods. As a result, the 7th edition remains a cornerstone in manufacturing education, equipping future professionals with the skills and insights needed to excel in a rapidly evolving field.

Core Topics Covered in the 7th Edition

The 7th edition covers modern manufacturing materials, processes, and systems, focusing on metal forming, casting, machining, and automation. It provides a comprehensive overview of production technologies and their applications;

2.1 Materials Used in Modern Manufacturing

The 7th edition extensively covers a wide range of materials used in modern manufacturing, including metals, polymers, ceramics, and composites. It highlights their properties, applications, and advancements in material science. The textbook explores how these materials are selected and processed to meet specific manufacturing requirements, emphasizing their role in achieving desired product performance and durability. Additionally, it discusses emerging trends such as lightweight materials, smart materials, and sustainable options, reflecting the growing emphasis on environmental considerations in manufacturing. The section also provides detailed insights into material failure analysis and strategies for enhancing material efficiency, making it a valuable resource for understanding the foundational aspects of material selection and utilization in contemporary manufacturing practices.

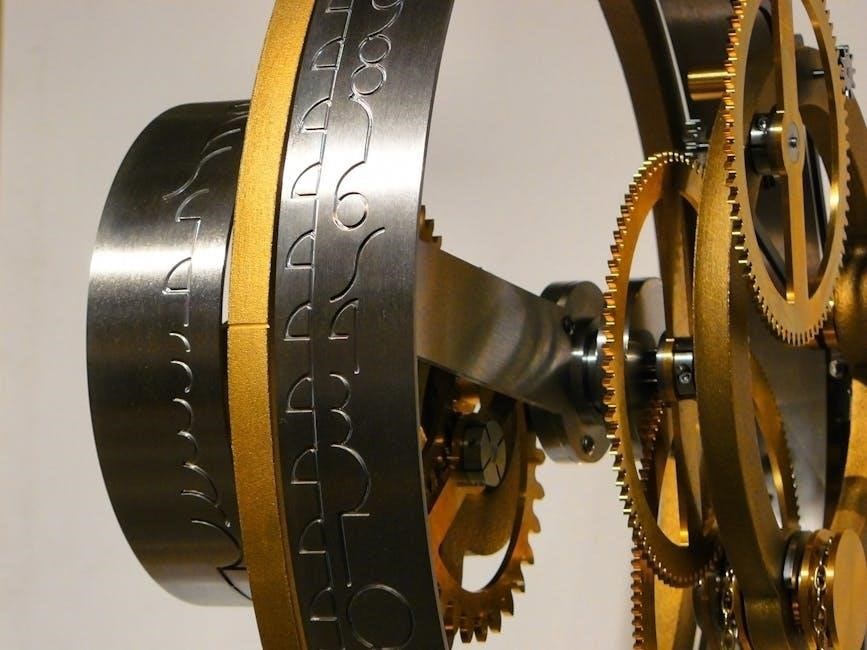

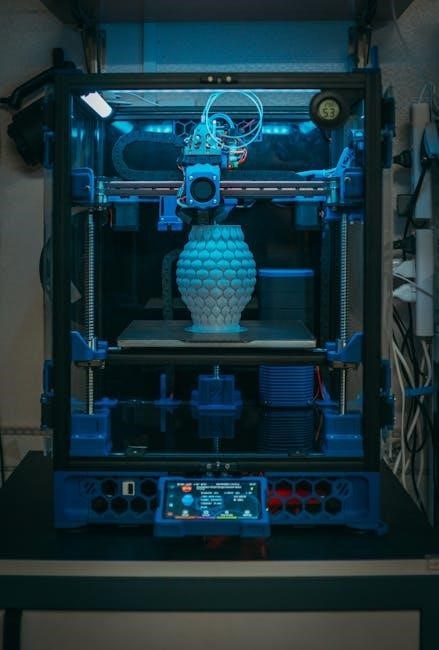

2.2 Manufacturing Processes and Technologies

The 7th edition delves into a broad spectrum of manufacturing processes and technologies, ranging from traditional methods to cutting-edge innovations. It explores metal forming processes like rolling, forging, and extrusion, as well as welding and casting techniques. The textbook also covers advanced manufacturing technologies such as 3D printing, CNC machining, and automation systems. These processes are discussed in detail, highlighting their applications, advantages, and limitations. The edition emphasizes the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) for precision and efficiency. Additionally, it addresses the role of robotics and Industry 4.0 in modern manufacturing, showcasing how these technologies enhance productivity and reduce costs. The comprehensive coverage of these processes and technologies makes the book an essential guide for understanding the evolution and implementation of manufacturing methods in today’s industrial landscape.

Advances in Manufacturing Systems and Automation

The 7th edition highlights advancements in manufacturing systems, including automation, robotics, and Industry 4.0. It explores how these technologies integrate with production control systems to enhance productivity and efficiency.

3.1 Production Control Systems

Production control systems play a pivotal role in modern manufacturing, ensuring efficient coordination of production processes. The 7th edition emphasizes the integration of advanced technologies, such as automated data collection and real-time monitoring, to optimize production workflows. These systems enable manufacturers to track inventory, manage orders, and schedule production effectively, reducing lead times and operational costs. The book also highlights the importance of feedback loops in production control, allowing for continuous improvement and adaptability to changing market demands. Modern production control systems are increasingly interconnected, leveraging Industry 4.0 principles to create seamless communication between machines and management layers. This integration enhances decision-making and ensures that production aligns with business objectives. The 7th edition provides detailed insights into these systems, making it a valuable resource for understanding their role in contemporary manufacturing environments.

3.2 Role of Automation in Modern Manufacturing

Automation has revolutionized modern manufacturing, enhancing efficiency, precision, and productivity. The 7th edition highlights how automation technologies, such as CNC machines, robotics, and IoT-enabled devices, streamline production processes. These systems minimize human intervention, reducing errors and improving consistency. Automation also enables real-time data collection, facilitating predictive maintenance and optimizing resource allocation. The book emphasizes the role of automation in scaling production while maintaining quality standards. Additionally, it discusses how automation integrates with production control systems, creating a seamless workflow. The adoption of automation not only reduces operational costs but also empowers manufacturers to respond swiftly to market demands. By detailing these advancements, the 7th edition underscores automation’s critical role in shaping the future of manufacturing, making it an indispensable resource for understanding modern industrial practices.

Quality Management and Continuous Improvement

The 7th edition emphasizes Total Quality Management (TQM) practices, highlighting their importance in achieving excellence and customer satisfaction. It explores methodologies for continuous improvement, ensuring high standards in manufacturing processes and products, fostering a culture of quality and innovation.

4.1 Total Quality Management (TQM) Practices

The 7th edition of Fundamentals of Modern Manufacturing delves into Total Quality Management (TQM) practices, emphasizing their critical role in achieving operational excellence. TQM is presented as a holistic approach that integrates quality into all aspects of manufacturing, from design to delivery. The book explores key principles such as customer focus, continuous improvement, and employee involvement, providing practical insights into their implementation. It also discusses advanced methodologies like Six Sigma and Lean Manufacturing, which complement TQM by reducing variability and waste. Case studies and real-world examples illustrate how TQM practices enhance product quality, reduce costs, and improve customer satisfaction. The chapter further highlights the importance of data-driven decision-making and the use of statistical tools in maintaining high-quality standards. By aligning TQM with modern manufacturing systems, the text equips readers with the knowledge to implement effective quality management strategies in industrial settings.

Importance of the Book in Manufacturing Education

The 7th edition of Fundamentals of Modern Manufacturing is a leading textbook for engineering students, offering a comprehensive understanding of manufacturing processes, materials, and systems. Its detailed coverage bridges theory and practice, making it essential for academic and industrial training.

5.1 Application of the Book in Academic and Industrial Settings

The 7th edition of Fundamentals of Modern Manufacturing is widely used in academic institutions for teaching manufacturing engineering courses. Its comprehensive coverage of materials, processes, and systems makes it an essential resource for students and educators. In industrial settings, the book serves as a reference for professionals seeking to implement modern manufacturing practices, including automation, quality management, and production control. The availability of the book in PDF and eBook formats enhances its accessibility for both classroom and industrial training. By bridging theory and practice, it supports continuous learning and professional development in the manufacturing sector.

No Responses